19.09.2023 | Press Release HRADIL Spezialkabel

The Deep Blue Sea High-Tech Cable

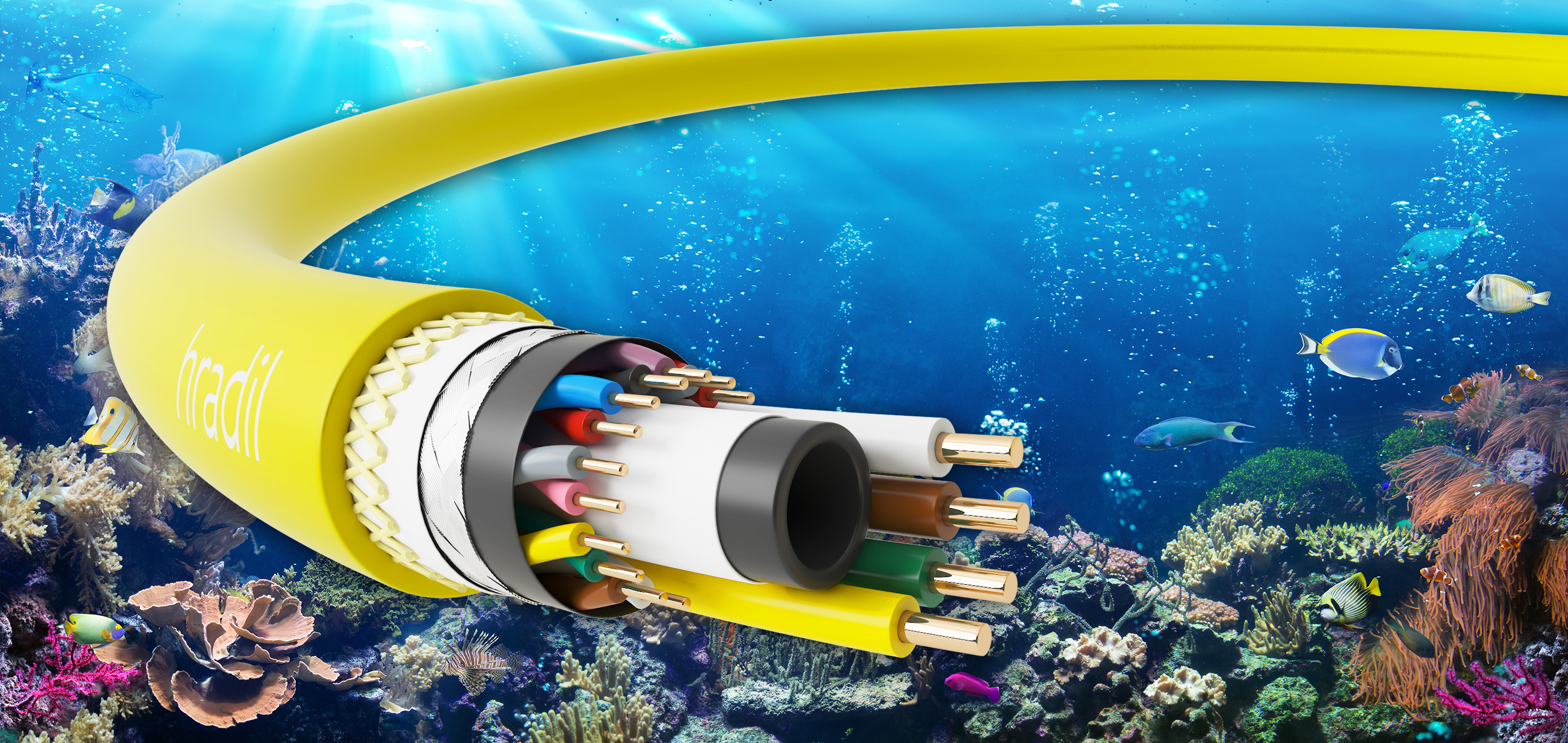

Hradil Spezialkabel from Bietigheim-Bissingen/Germany have developed a data transmission and power supply cable with a length of up to 200 meters to operate remote-controlled submersible vessels(*). The new maritime deep-sea cable is predestined for scientific and commercial tasks in the fields of marine research and exploration. With an outer diameter of 19 mm this specialist cable comprises six internal twisted pair conductors for Ethernet (RS485 / Cat5), 4 conductors for power supply as well as a centrally placed compressed air hose.

Authors: Dede Bülbül, Managing Director and Director of Technology and Alfred F. Hradil, CEO

Fig 1: Hradil Data transmission and power supply cable to operate

remote-controlled submersibles for marine research and exploration

Remote-controlled monitoring technologies offer interesting possibilities that are used across a wide range of research areas, such as biology, archeology, geology and meteorology. Drones, for example, can be equipped with audio, video or infrared sensors to fulfil highly useful scientific near-earth exploration tasks. Due to the special pressure conditions prevailing in marine environments and having to operate in water, research is much more difficult here. However, it is not so much the submersible vessel as such that poses challenges, but the power supply and data transmission cable, that provides the vessel with the necessary energy and compressed air, and, in the worst case, also functions as a lifeline.

What Is The Maximum Weight For An Under-Water Cable?

Weight is the crucial factor for cables designed for use on submersible vessels. This is how Dede Bülbül, Chief Engineer and Director of Technology with Hradil Spezialkabel explains the design challenge for cable engineers: “The cable should always hover in the water regardless at which depth the submersible operates at any given point in time. On the one hand the supply line must not be too heavy as it would drag down the submersible, on the other, it shouldn’t be too light either, as the vessel would not even begin to go down or the cable would pull it back up”.

As the core’s copper conductors have a specific weight which far exceeds that of water – 8.9g/cm³ to be precise - you want to use some other materials, too, such as standard compounds, which have a lower specific weight than water to compensate for the heavier weight of the copper.

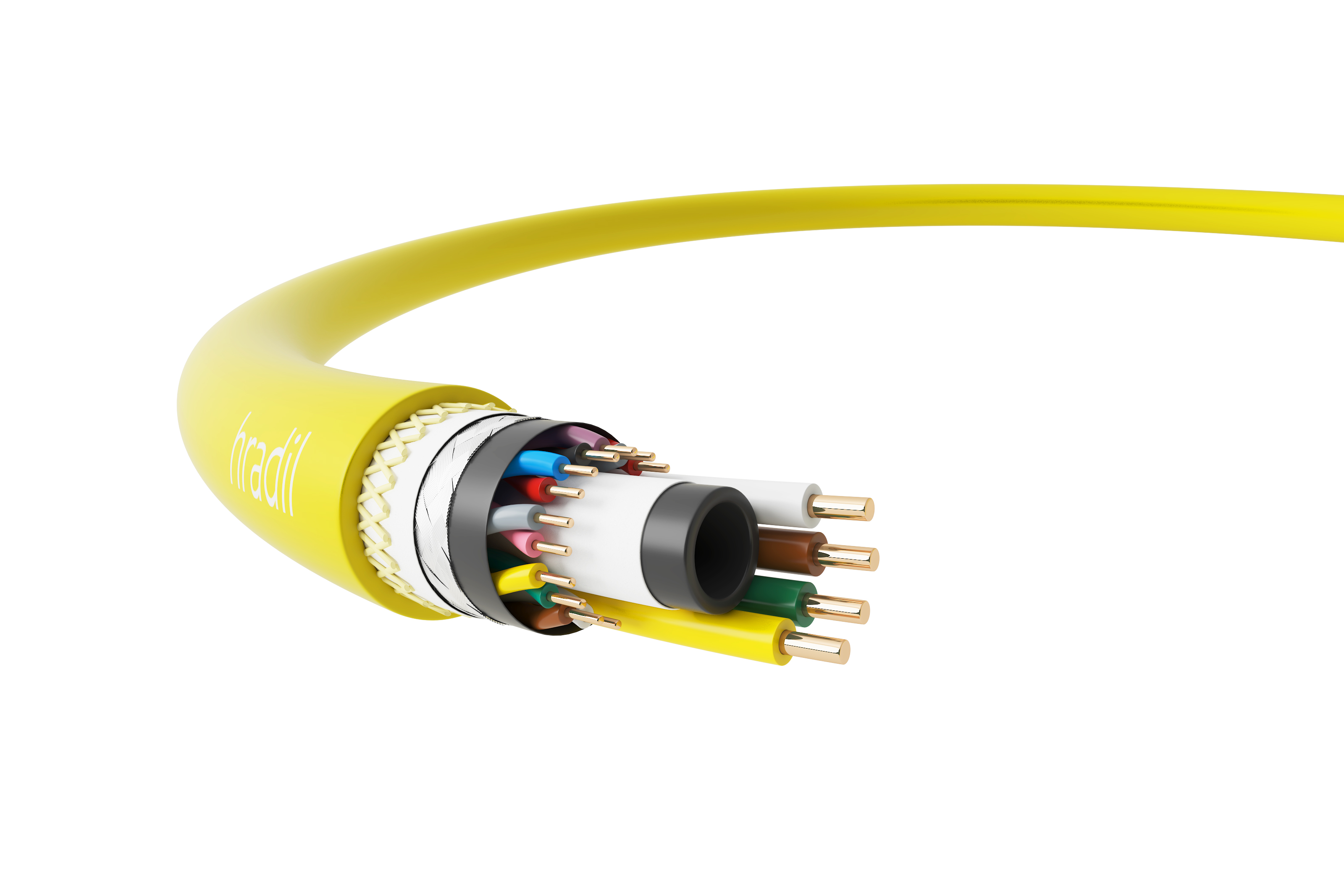

Fig 2: Hradil Maritime Data Transmission and Power Supply Cable for

Maritime Research and Exploration with Submersible Vessels

Innovative Cable Designs Required to Cope With High Pressure Levels

The pressure rises with increasing immersion depth. For every 10 meters additional depth the pressure rises by 1 bar. At a depth of 10 meters, the outer pressure acting on the submersible and the cable is twice the pressure at the surface of the water, at a depth of 20 meters it is triple that. The effect of this on the cable would be that that the deeper the depth, the greater the deformation would be. Simultaneously, also the physical properties of the buoyancy-enabling porous materials inside of the cable would change. In other words, the further down you go, the more the cable would lose its buoyancy characteristic and eventually drag down the submersible with it.

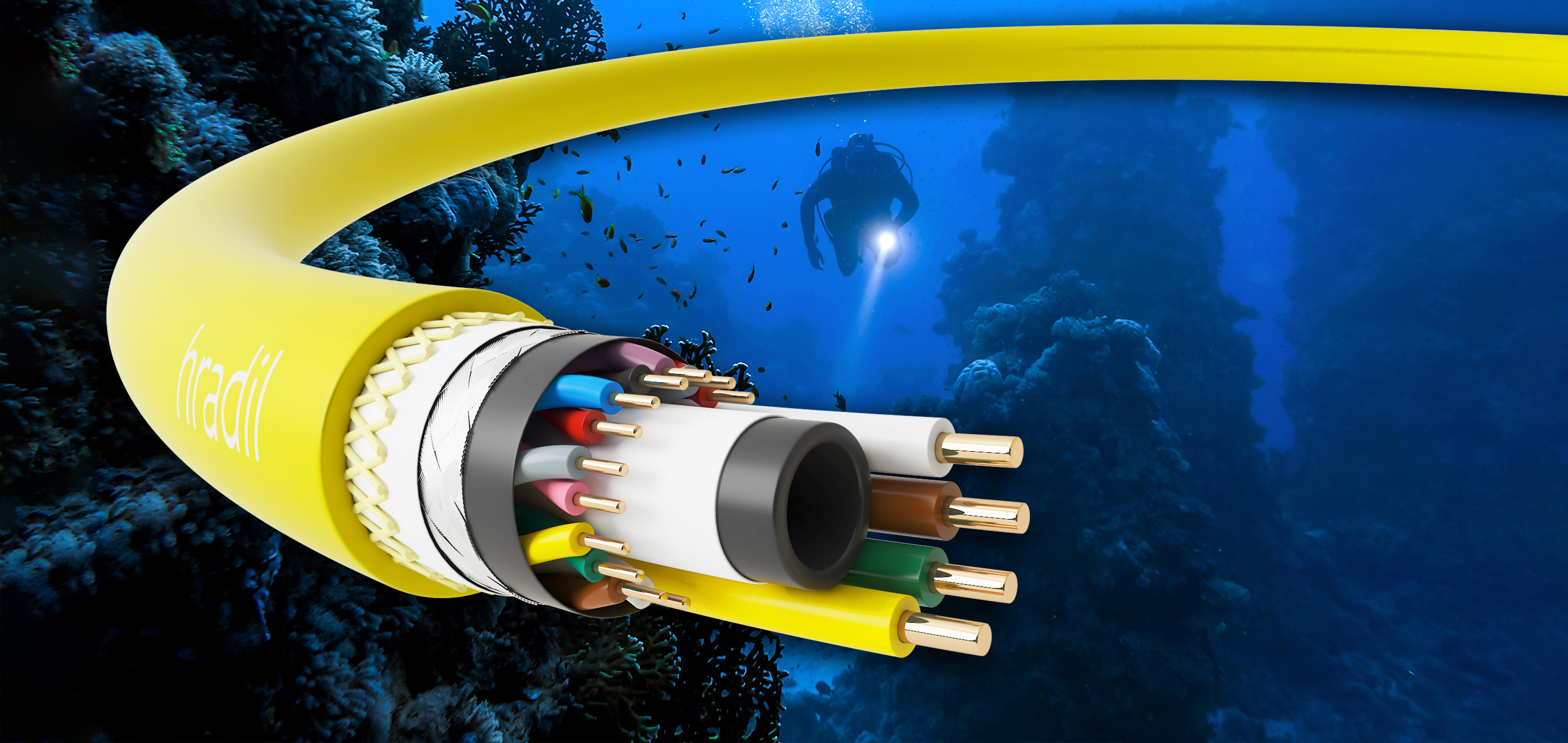

Fig 3: Hradil Maritime Data Transmission and Power Supply Cable

for Maritime Applications with Submersible Vessels

Fig 3: Hradil Maritime Data Transmission and Power Supply Cable

for Maritime Applications with Submersible Vessels

The Hradil Deapsea Cable Solution

Hradil’s engineers have now come up with a technical solution featuring no porous buoyancy materials whatsoever. Instead, Hradil opted for a more pressure-resistant design featuring a special hose at the center of the cable that can be filled with compressed air with the help of a motorised pump. This permits to increase or decrease the pressure inside of the cable in order to compensate the water pressure acting on the cable depending on the operating depth of the submersible, thereby providing the necessary buoyancy.

The special cable was specially designed so that submersible vessels can carry out all research and exploration tasks successfully. As Dede Bülbül explains: “We scrutinized the different functions submersibles are expected to fulfil, and, based on this analysis have designed a cable that does the trick with only half the number of conductors compared to standard cables. It’s outer diameter of only 19 mm is a great advantage because this makes for excellent drum-reeling capabilities”. To transmit the data from the different marine sensor systems on the submarine, the Hradil cable is equipped with a total of 6 twisted pairs for ethernet, sensors etc. and 4 conductors for 2300/500V power supply.

It’s bending radius of 190 mm and tensile strength of 8,000N make the cable perfect for the harsh maritime conditions onboard of ships. The temperature range is --30°C to +85°C. The cable by Hradil has been designed for abrasive use and is resistant against ozone as well as UV radiation.

(*) What’s a submarine? What’s a submersible?

The National Oceanic and Atmospheric Administration website (US Department of Commerce) explains the difference between the two. "A submarine has enough power to leave port and come back to port under its own power.” This means that a submarine can drive independently to the bottom of the ocean and come back. The administration says: “A submersible has very limited power reserves so it needs a mother ship that can launch it and recover it.”

(https://oceanexplorer.noaa.gov/edu/oceanage/04widder/transcript.html)